News

News from the Sublitex world

Three local excellences form a system and give life to a new way of conceiving industry 4.0

Sublitex, a company of the Miroglio Group, world leader in the transfer paper and technical film sector, Dromont, a leading company specialized in the construction of industrial plants for mixing inks and paints, and Bianco, a leading company in the design and production of machinery textiles, have pooled their skills to create a new and competitive way of conceiving the industry.

A “glocal” approach, both globalized and local, is what characterized the new collaboration born between the three companies. All with a strong international scope and always committed to making the world their market, they have chosen to look to their territory of origin to create synergies and to emphasize the importance of "know-how" and "know-how to innovate" made in Alba .

Hard work, dedication, attention to detail, innovation and excellent business results are the characteristics that have contributed over the years to making our city that example of virtuous reality that everyone recognizes. Values in which Sublitex, Bianco and Dromont deeply believe and on which they want to continue to bet to be even more competitive in the future and to continue to propose innovative Industry 4.0 models.

The term Industry 4.0 indicates a trend in industrial automation that integrates some new production technologies to improve working conditions, create new business models and increase the productivity and production quality of plants. Dromont and Sublitex create an innovative "Color Kitchen"

Sublitex and Dromont have joined forces to design and create an innovative "color kitchen", which is now active at the Sublitex plant in Alba.

The "color kitchen" is an automatic mixing system which, in an absolutely precise way and with a very high quality output, allows you to prepare functional color preparations to feed the most sophisticated printing systems.

The new “Genius” system, created by Dromont together with (and exclusively for) Sublitex, joins the traditional “color kitchen” already born years ago from the collaboration between the two companies. Unlike the previous one, this new machine - which is the state of the art in its sector - will allow to operate with a precision hitherto unthinkable even in the mixing of "wood effect" paints, allowing Sublitex to achieve an impeccable result even in its new films for window frames.

Thanks to its latest generation features, the new "color kitchen" will allow you to:

Guarantee an optimal yield in every preparation of the color “recipes”, as they are managed by spectrophotometric processes of the highest quality and by a system with refined mechanics.

Ensure perfect repeatability over time of each "recipe" since the percentages of "color ingredients" are determined digitally and can be stored.

Increase the safety of the work environment, being fully automated and equipped with powerful suction systems (connected with the Regenerative Thermal Oxide system, already present and active in Sublitex).

Promote an important respect for the environment in terms of eco-sustainability, guaranteeing, thanks to a superfine mechanics, a dosage of the highest precision and the minimum possible consumption of raw material.

Bianco and Sublitex create a modern "Robotized Island"

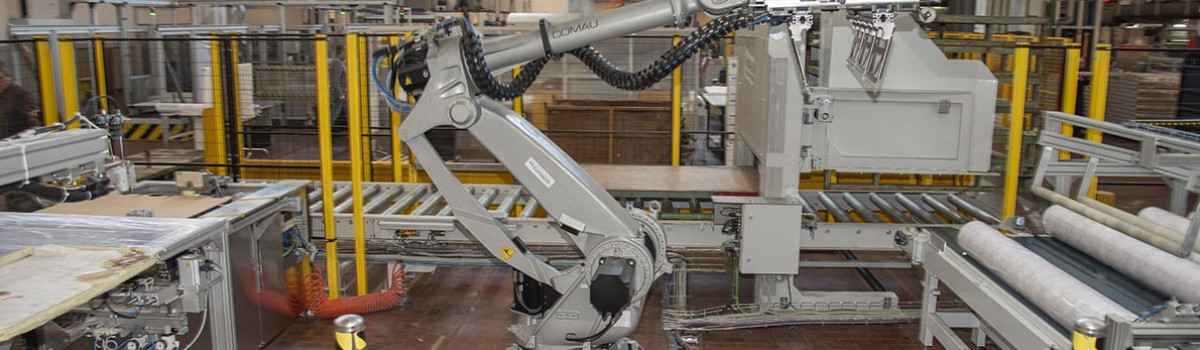

Sublitex and Bianco worked together to design and create a modern and functional "robotic island for boxing and palletizing for the end of line", which has been operating for several months at the Sublitex plant in Alba.

The island is a futuristic industrial plant capable of palletizing the most varied types of products directly on pallets or pallets, providing previously - and in a totally automatic way - for their boxing. All in an extremely protected environment as it is delimited by safety light curtains and in which the operator's intervention is limited to the loading, programming and unloading phases of the finished product.

The new "IPR-1" plant, created by Bianco specifically for Sublitex, is a flagship in the field of industrial automation and will allow Sublitex to make end-of-line processes even faster and safer, from the procurement of materials of packaging, to the storage of its own reels, thanks also to a real-time synchronization of the island with the M2Log logistic center of the Miroglio Group.

Thanks to its latest generation features, the new "robotic island" will allow:

Make all the boxing and palletizing phases of Sublitex reels faster and safer thanks to a totally automated process, in which human input is limited to the more tactical programming parts and to those of loading and taking (upstream and downstream of the process) .

Promote immediate integration with industrial logistics operations, instantly transmitting to the "M2Log" Advanced Industrial Logistics Center (Castagnole delle Lanze) all the data relating to the "outgoing" packaging material and the "incoming" reel. In this way, real time scheduling of stocks and deliveries becomes possible, in full line with the prerogatives of a modern 4.0 system.

Optimize the time required for the "format change" of the reels to be palletized. The format change is very fast as it is programmed upstream of the process and becomes fast.