News

News from the Sublitex world

SUBLITEX towards an increasingly sustainable production.

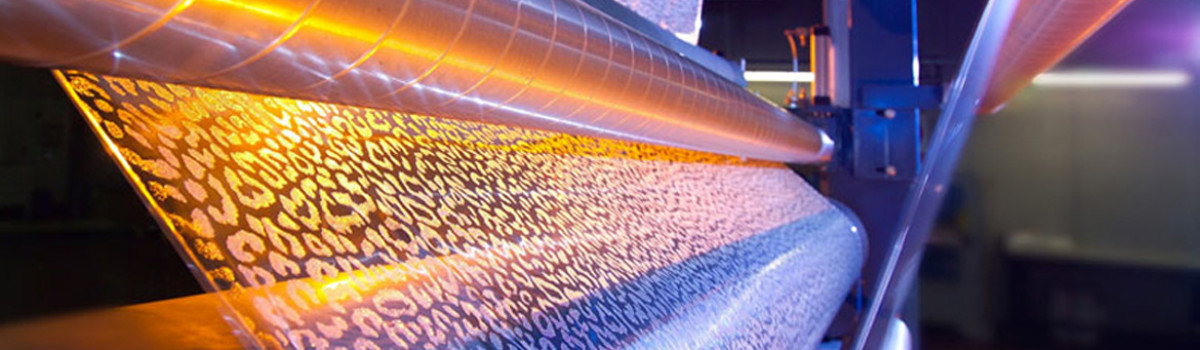

Sublitex becomes more and more sustainable thanks to the development and adoption of industrial solutions with reduced environmental impact, from the energy-efficient Water-free printing process, to the recovery of inks and fumes, up to its first capsule of recycled polyester fabrics.

Thanks to a constant investment in technology, Sublitex in fact decorates over 60 million square meters of supports and surfaces all over the world through water free and energy saving printing processes, both for digital technology and for traditional rotogravure. Water consumption went from 101 cubic meters per ton produced in 2010 to 15 cubic meters per ton in 2018, with a reduction of 85%. This corresponds to a saving of 210 thousand cubic meters of water per year, which is equivalent to the water needs of 2,700 people. Furthermore, by not using water in the printing process, the creation of waste water is avoided, further reducing the environmental impact.

Rotogravure printing is carried out with ethanol-based inks - a natural and renewable substance - and all the inks used in the production process are entirely recycled using an ink recovery technology. The special "Color Kitchen" by Sublitex makes it possible to increase the safety of the workplace and promote respect for the environment thanks to a very high precision dosage and reduced consumption of raw materials. The paper production process and the transfer of the design to the fabric are also carried out using ecological techniques.

Thanks to particularly innovative digital printing techniques, Sublitex is able to combine the advantages of digital with the profitability and economies of scale of traditional technology: the "Just in time" execution speed and the perfect repeatability of the designs allow to reduce the warehouse costs for printed material and ink consumption is limited to the print request, thus limiting the amount of residual materials for processing.

Recently Sublitex has also installed a Regenerative Thermal Combustor (OTR), which allows a correct exhalation of the production fumes. The captured printing vapors are conveyed to this innovative regeneration system, which destroys the harmful substances contained in the fumes, optimizing consumption and allowing a very low environmental impact.

Among the latest Sublitex projects there is also a capsule of recycled polyester fabrics, printed with transfer technology in a completely water free way. The capsule is part of the "Urban" collection, with which the company moves from its classic business of technical films to embrace the printed fabric market further downstream. The initiative originates from the post consumer recycling of PET and polyester garments.

As proof of Sublitex's strong commitment and results in the direction of ever greater sustainability, since 2020 the company is an official partner of the Bluesign system, which brings together companies that have made sustainability a philosophy and act responsibly in the textile production chain, committing themselves to implement environmental standards in the supply chain. In addition, the company has an integrated certification system, being accredited to ISO 9001 (on quality management), OHSAS 14001 (for environmental management) and OHSAS 18001 (for health and safety).

Thanks to particularly innovative digital printing techniques, Sublitex is able to combine the advantages of digital with the profitability and economies of scale of traditional technology: the "Just in time" execution speed and the perfect repeatability of the designs allow to reduce the warehouse costs for printed material and ink consumption is limited to the request for the printed material, thus limiting the amount of residual materials for processing.

Recently Sublitex has also installed a Regenerative Thermal Combustor (OTR), which allows a correct exhalation of the production fumes. The captured printing vapors are conveyed to this innovative regeneration system, which destroys the harmful substances contained in the fumes, optimizing consumption and allowing a very low environmental impact.

Among the latest Sublitex projects there is also a capsule of recycled polyester fabrics, printed with transfer technology in a completely water free way. The capsule is part of the "Urban" collection, with which the company moves from its classic business of technical films to embrace the printed fabric market further downstream. The initiative originates from the post consumer recycling of PET and polyester garments.

As proof of Sublitex's strong commitment and results in the direction of ever greater sustainability, since 2020 the company is an official partner of the Bluesign system, which brings together companies that have made sustainability a philosophy and act responsibly in the textile production chain, committing themselves to implement environmental standards in the supply chain. In addition, the company has an integrated certification system, being accredited to ISO 9001 (on quality management), OHSAS 14001 (for environmental management) and OHSAS 18001 (for health and safety).